The main project for the past week has been the bow roller. I doubt my boat’s roller can be an example for any of your projects and it might even look strange to most of you but remember that I am building a steel replica of a wooden traditional sailing tuna fishing boat. The most components I will integrate to the original look of those work boats the happier I will be about the results.

Obviously, I can’t build an authentic copy of a 1930 tuna fishing vessel; first because I’m working with steel but also because I can’t loose site of safety and functionality of a cruising vessel.

I had been looking forward to build a bow roller on the Pepe Berrou as it is one component that is a particular characteristic of the vessels I want to model, but that will also be very useful with little compromise.

For now I am only building the frame of the roller and will come back to the axle and roller itself later. The reason is that, for now, I am concentrating on all welding jobs that need to be done before sandblasting and painting the interior.

A little piece of history:

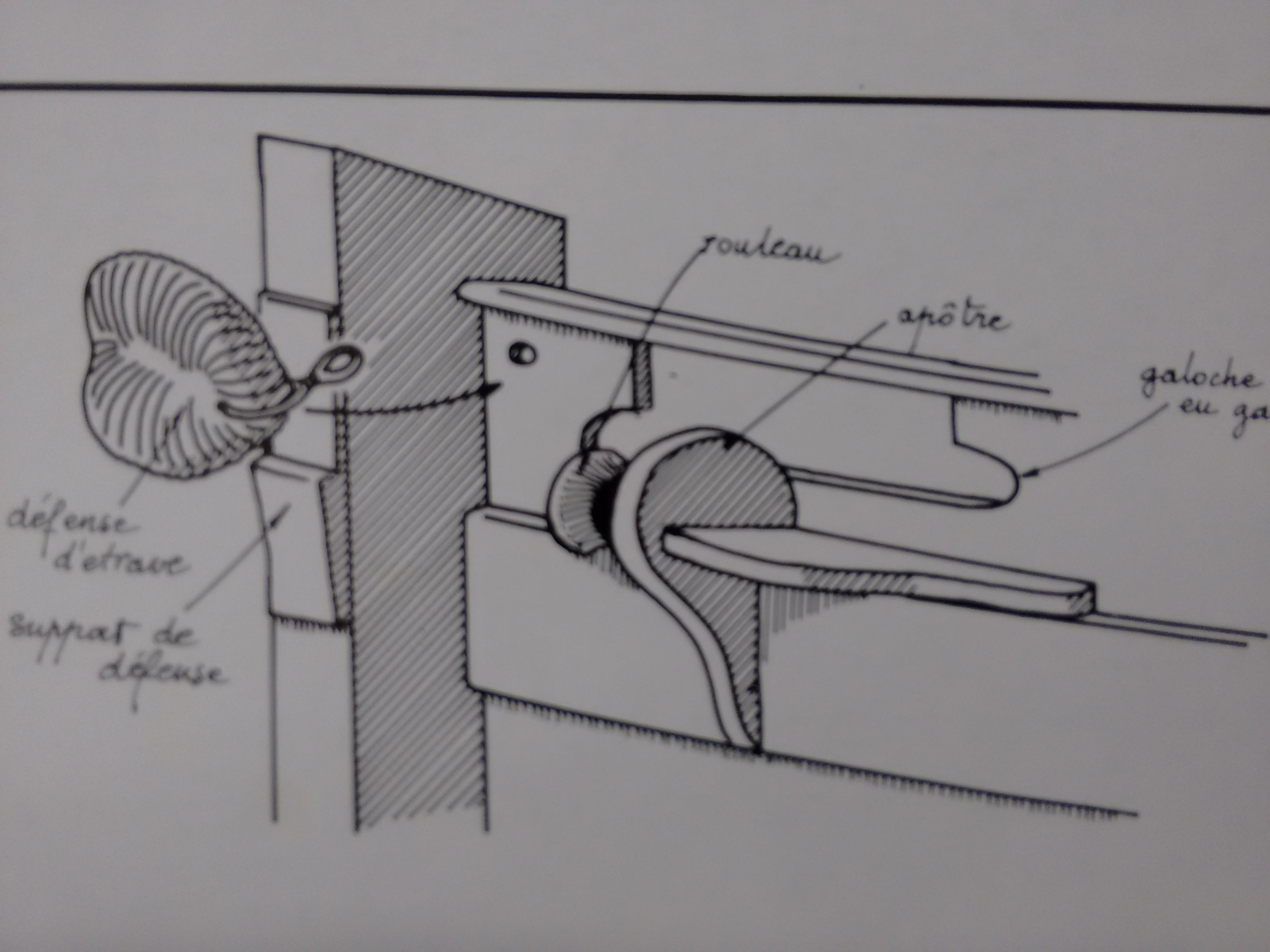

The main purpose of the bow roller on the tuna fishing boats was not to reel in an anchor but a fishing net. Before the industrial fisheries, tuna fishing was seasonal. The boats would go out catch the fish during there migrations. To make a better living and amortize there boat the Brittany fisherman had to to double the boat’s function as net dragging boats. The big roller was used to maneuver the massive net and it’s load.

The opening around the roller was huge and would extend behind it to drag the net without pulling on the “ear” of the roller.

On our boat I kept the opening more reasonably small, extending it just enough to allow a mooring line to be pulled back. This is not too much of a compromise in the looks as it was more powerful vessels that would be used for dragging….and…well, as big as it seams to us our boat would only be a baby fishing boat on the scale we are playing with.

Originally I was going to build the “ear” out of a 1/4 in plate and most likely double it with a wood piece to give it the volume. For the sake of a bit more work, what made more sens was to build a box section out of 1/8 plate. The result looks right and is much stiffer.

This part of the project was a lot about looks and my artsy mind really enjoys that. Their was some geometrical challenges to get the proper shapes for the plates to line up square and at the right positions, my technical mind had fun with that.

There are so many boring jobs to be done, a small project with good visual progress was quite welcome at this point, those are needed to keep enough motivation threw the project.